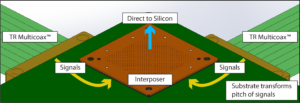

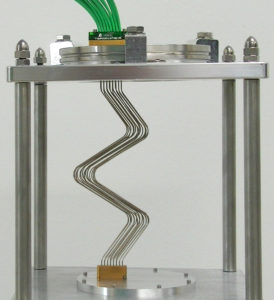

The newest form factors of Ardent’s TR Multicoax connectors support the many unique challenges of Quantum Computing applications. Density, substantial environmental changes, and an increasing need for more high-speed lanes are causing quantum computer designers to rethink traditional routing methods of individual cables.

Ardent’s existing patented contact technology allows engineers to drastically decrease real estate required by individual connectors and increase their channel count while improving signal integrity in their systems.

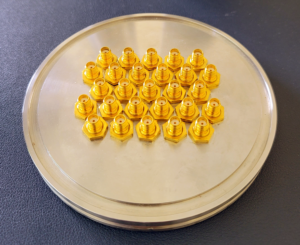

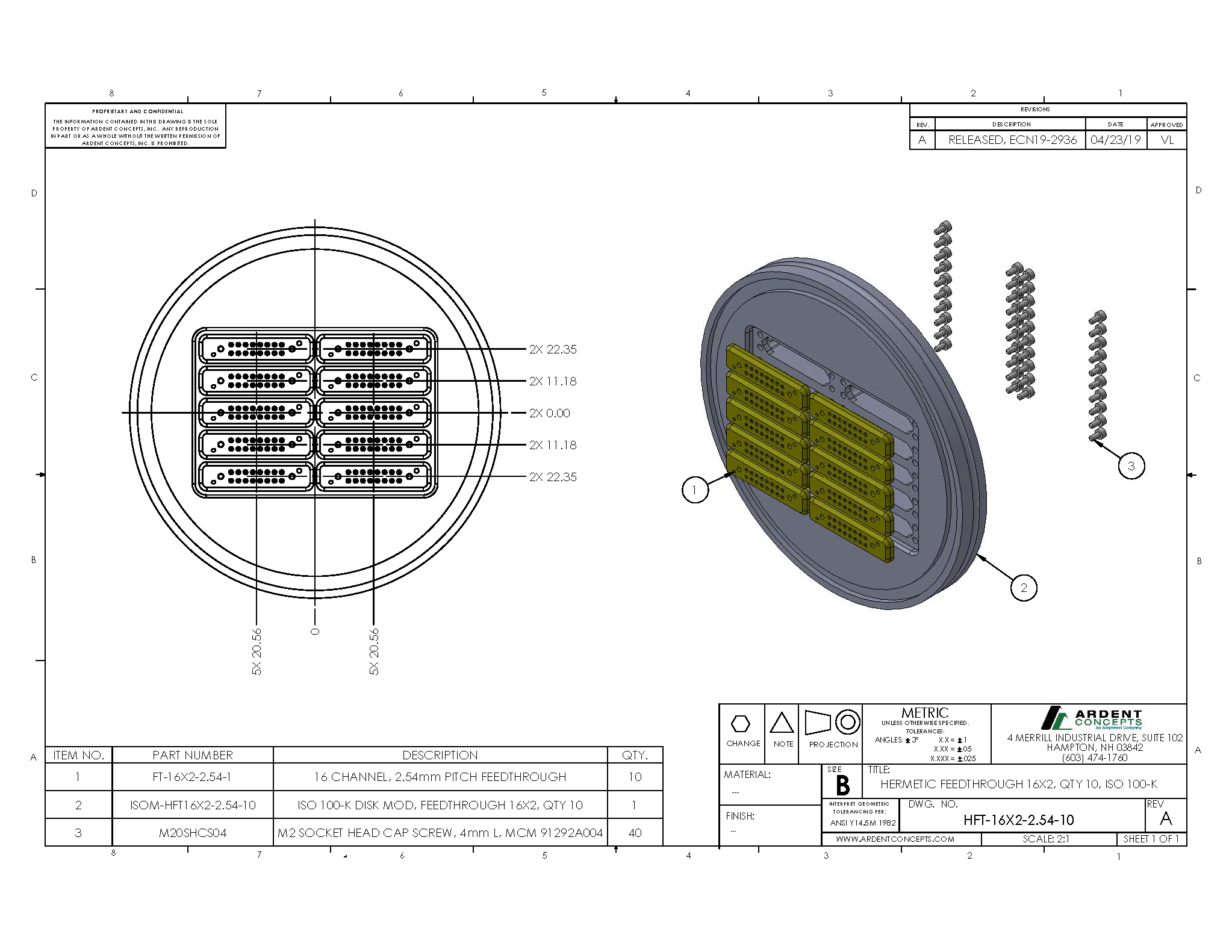

- 50Ω ganged hermetic feedthroughs offer leakproof design

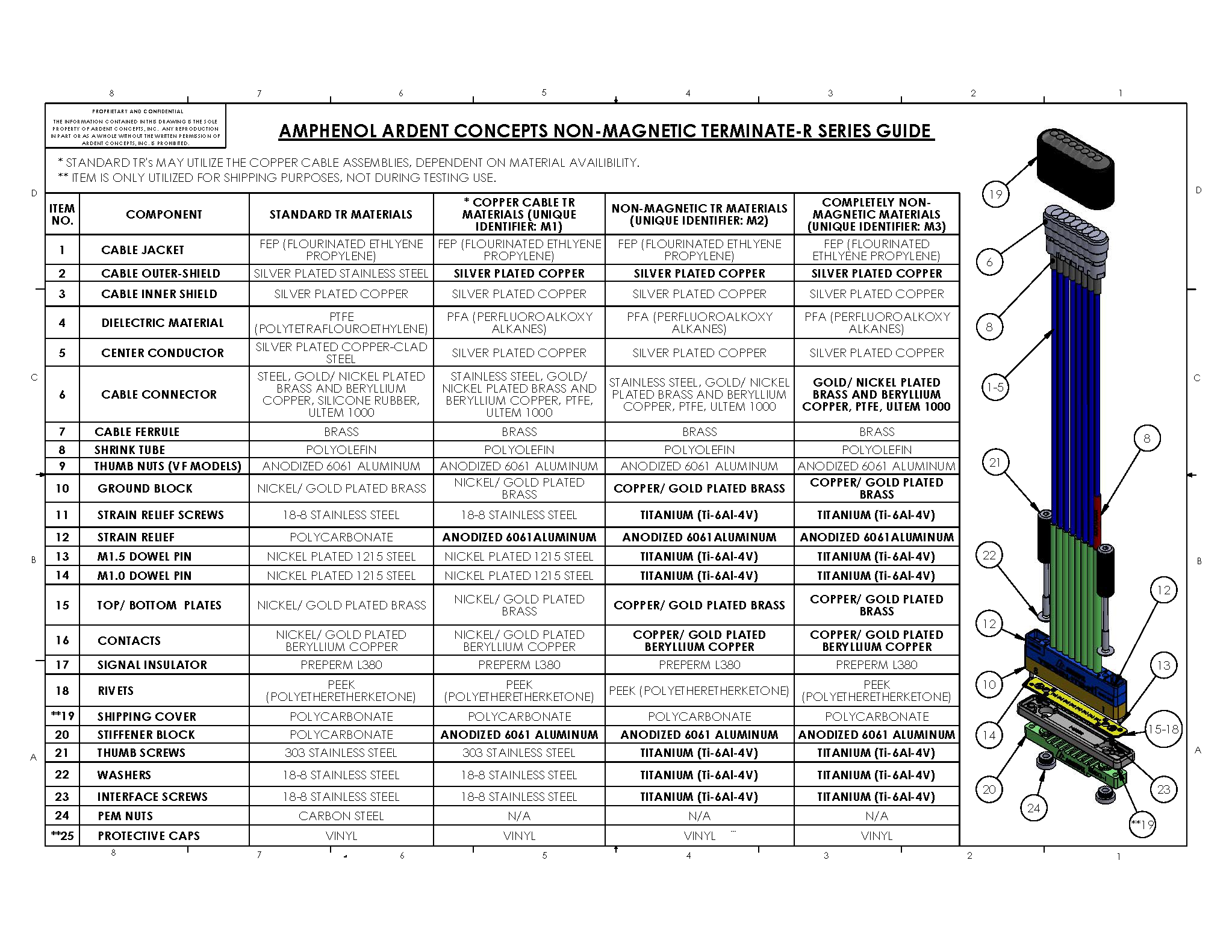

- Variety of coaxial cable materials available (e.g. Flexible, CuNi, Non-Magnetic)

- Extremely dense form factor (168+ channels in standard ISO disc)

- Easily mate/de-mate multiple high-speed lanes

Quantum Computing / Cryogenic Applications

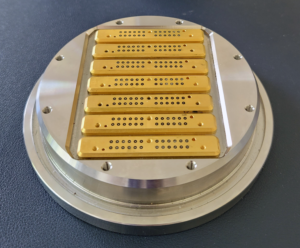

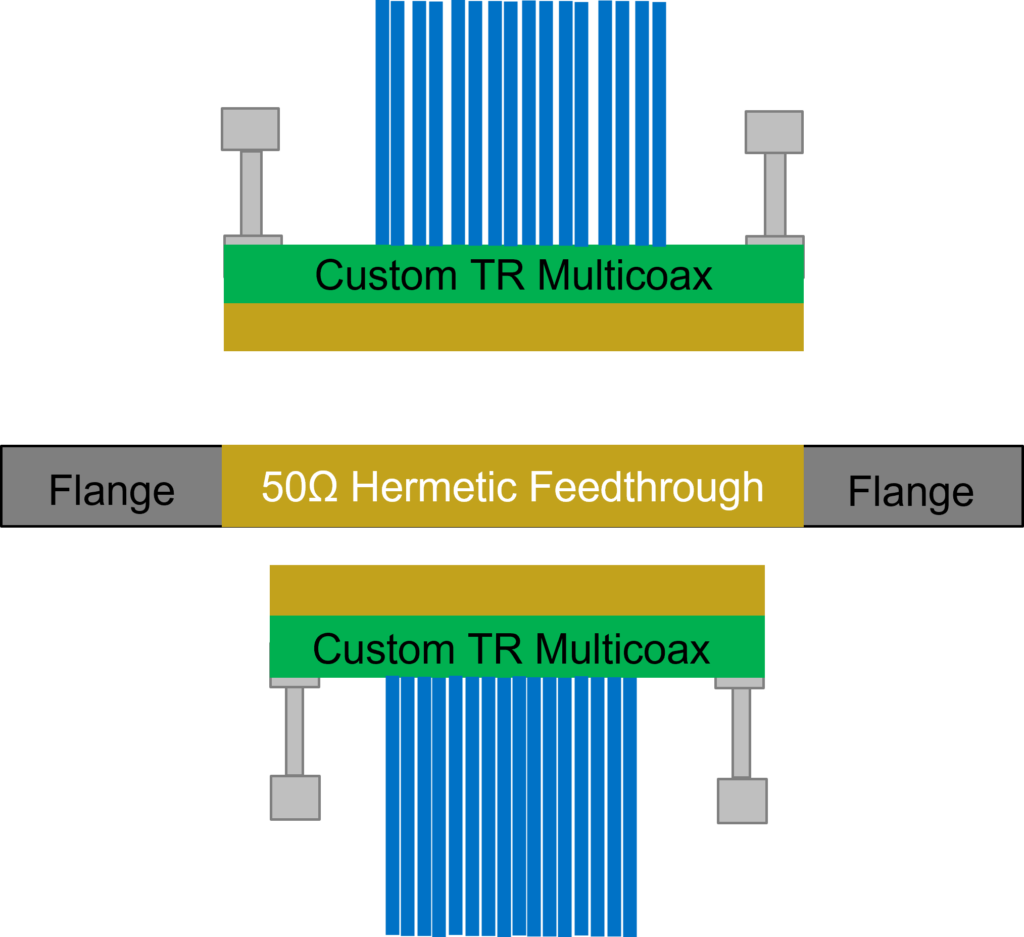

50Ω Hermetic Feedthrough

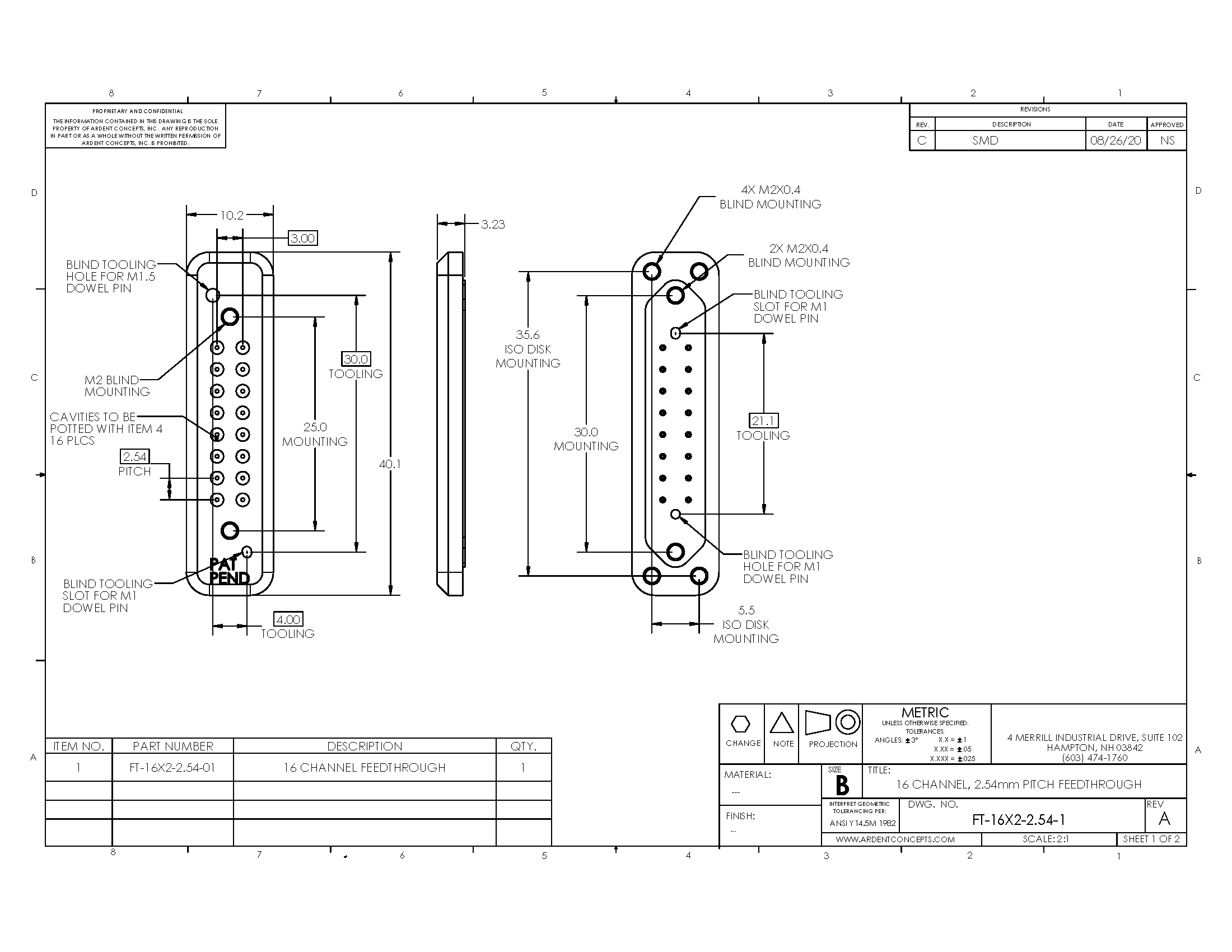

- Ardent TR Multicoax™ compatible – substantial channel increase over traditional surface mount connectors (2.54mm pitch)

- Can be prepopulated in vacuum flanges, customer specific flanges, or sold individually

- Allows quick connection of multiple TRs at once

- Robust interface – rated up to 1000 mating cycles

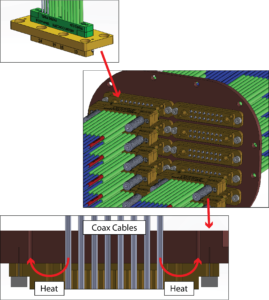

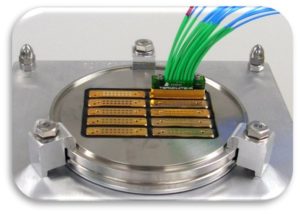

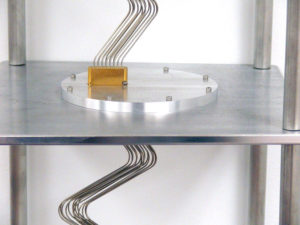

High Density TR Multicoax™ Cabling

- High Density (2.54mm pitch) TR Multicoax™ bridges room temperature electronics to Hermetic Feedthrough for massive lane scale up

-

Internal coaxial cabling options include:

• Low outgassing flexible

• Semi-rigid

• Non-magnetic - All metal, fully coaxial solderless compliant interface between connectors allows for noise floor crosstalk

- Assemblies available in a variety of form factors, cable lengths, and pre-bent configurations (consult factory with requirements)

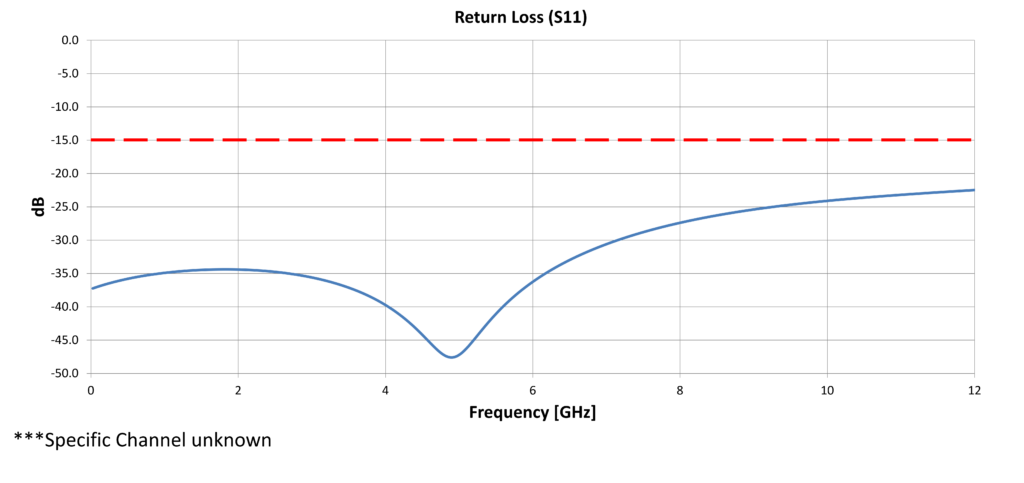

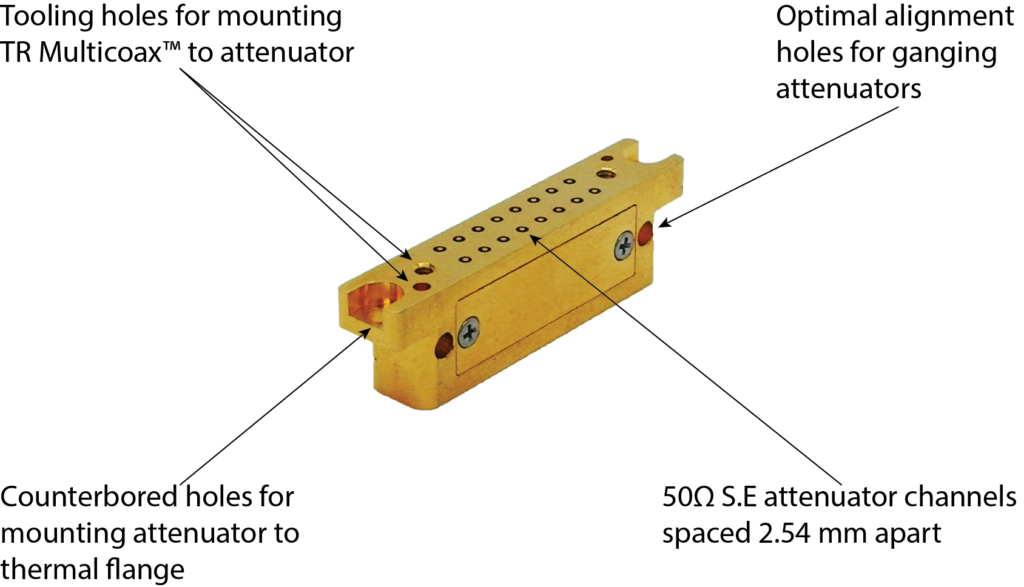

In-Line Cryogenic Attenuation

- TR Multicoax™ compatible – Substantial increase in channel density over traditional SMA style in-line attenuators

- Chip-style cryogenic attenuator design on thermally conductive dielectric (conductive epoxy bonded substrate)

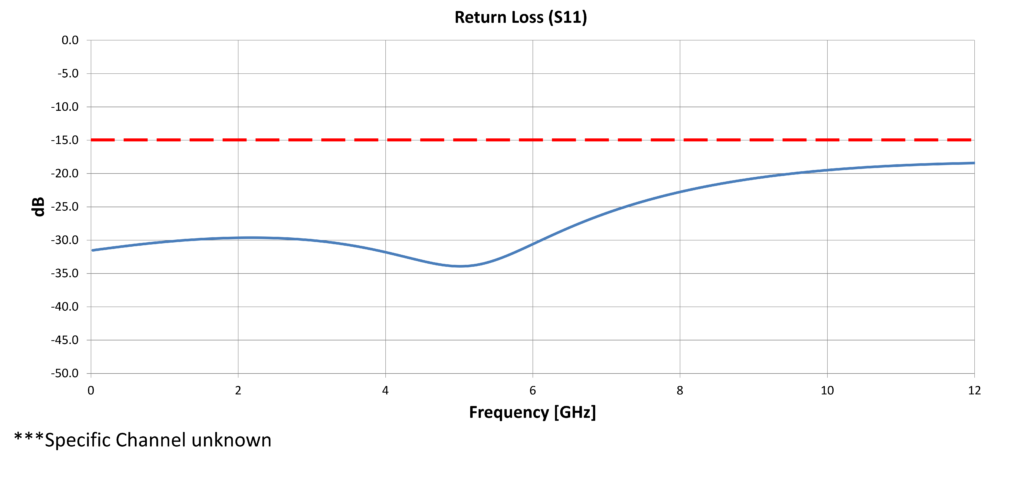

- Frequency: DC to 12 GHz

- Multiple attenuations available from 0 to 20 dB

- 16-channel (2×8) form factor (consult factory for additional form factors)

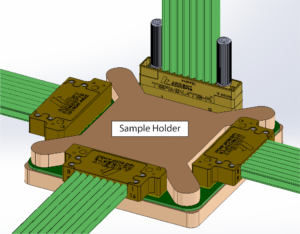

Advanced Near-Processor Solutions

- Customizable TR Multicoax™ assemblies for connection of final stage to processor

- Light blocking connection between stages

- Right angle low-profile form factors for near processor connection

- Cryogenic and vacuum compatible socket and interposers for chip-to-board and board-to-board connection

- Down to 0.4mm pitch pin-to-pin

- Non-magnetic and low outgassing material options

Ardent Solutions

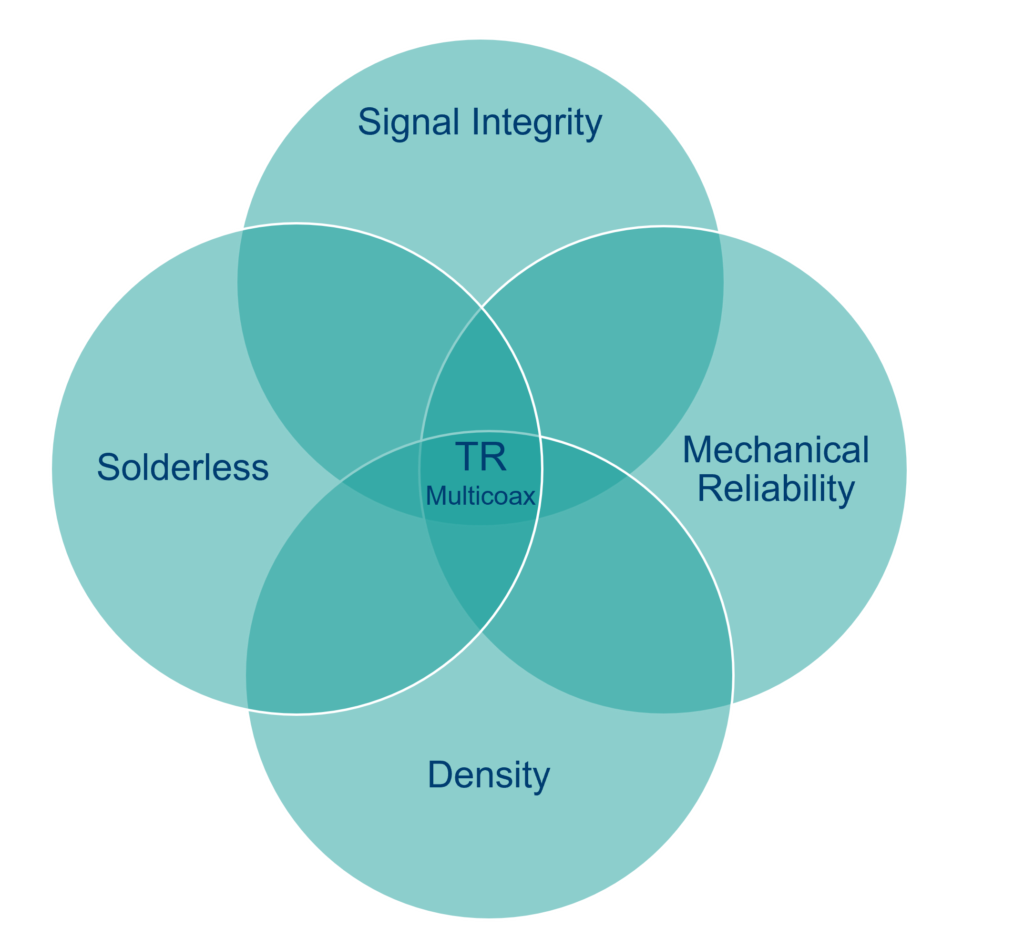

Signal Integrity

Signal Integrity

Ardent’s interconnect technology was born of a simple concept: What if we could eliminate the barrel and the plunger from a traditional “pogo” style spring pin and make the spring inside behave like an electrical contact instead of behaving like an inductor at multi-GHz speeds?

Solderless

Our products are all based on solderless compression mount technology enabling more reliable and electrically repeatable performance over time and across programs. Our solderless compression products allow our customers to be agile in changing their designs without having to scrap entire projects and printed circuit boards with components soldered to the board. This leads to enhanced flexibility and cost savings.

Density

Contacts can be arranged in pitches down to 0.4mm (grid array) and 2.54mm signal-to-signal (coaxial array) to scale up the number of lanes in any system.

Mechanical Reliability

Mil-Spec qualified and rated for thousands of cycles in the harshest environments, Ardent’s patented technologies are production proven with over 19 years of field use for test and measurement and OEM interconnect.

- Scalable solutions for connectors down to 0.4mm pitch

- Eliminates the barrel and the plunger from a traditional “pogo” style spring pin (fewer mechanical components to fail)

- Patented “wipe action” of the coils causes contacts to behave like a solid element instead of behaving like an inductor, resulting in exceptionally clean AC performance in an extremely short electrical path

Description

Description

The TR Multicoax is a compression mount, multi-port cable assembly for carrying high speed signals. With true 70 GHz performance, TR is the highest performing solderless connector solution on the market today.

Compared to traditional solder down coaxial connectors like SMAs and SMPs, TR Multicoax takes up 80% less space and is easily re-usable as it can be moved from position to position without the need for any surface mount components.

Applications

- Near-QPU

- Dilution Refrigerator/Cryostat

- Room Temperature Electronics

- Vacuum Chambers

- Using patented spring probe technology, the TR Multicoax combines the Ardent Interposer technology and coaxial cable technology to create an unsurpassed solderless connector solution

- By carefully controlling the geometry and material properties, the Ardent Interposer technology minimizes impedance discontinuities in an extremely electrically short transition enabling 70 GHz + performance

Description

Description

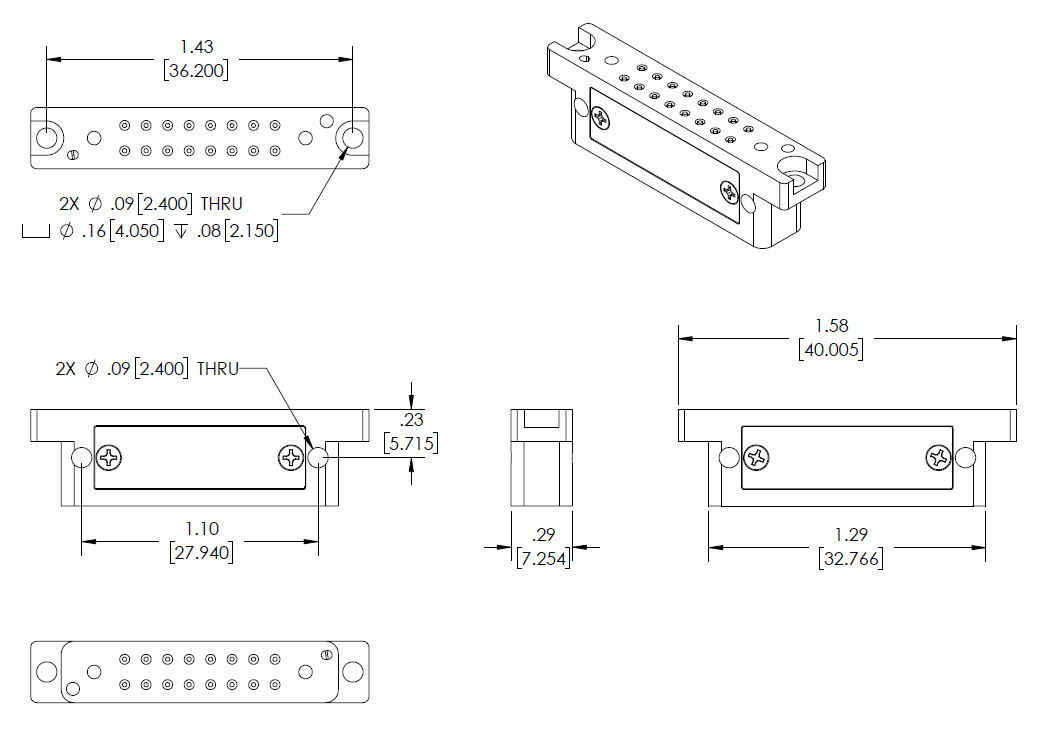

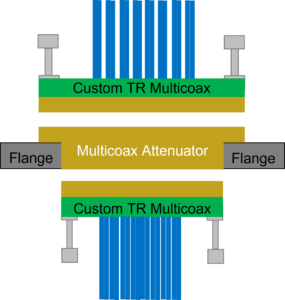

50Ω Hermetic Feedthrough is ideal for applications where hermeticity is crucial to the transmission of RF signals. In these applications, TR Multicoax connectors are mated to the hermetic feedthrough on either end ensuring an impedance matched 50Ω channel between any two chambers. The feedthrough is fixed to a flange (such as an ISO disk) with screws in blind holes from the inside of the vacuum. Each channel on the hermetic feedthrough is completely sealed using an epoxy potting.

Applications

- Dilution Refrigerators/Cryogenic Devices

- Quanum Computing

- Vacuum Chambers

- Defense/Aerospace

TR Multicoax 50Ω Hermetic Feedthrough: 168 RF Lanes

SMA 50Ω Hermetic Feedthrough: 27 RF Lanes

Description

Description

High density thermalized low noise cryogenic bulkhead attenuator array for use with TR Multicoax™ connectors. Utilizes industry leading materials like Oxygen-free high thermal conductivity (OFHC) copper and NiCr on thermally conductive crystalline quartz dielectric provides minimal change in attenuation with temperature delta. Attenuation is offered in 0, 10, and 20 dB configurations and supports bandwidth up to 12 GHz. 16 channel form factor at a 2.54 mm pitch, signal to signal, saves valuable real estate in confined spaces.

Applications

- Dilution Refrigerators/Cryogenic Devices

- Quanum Computing

- Vacuum Chambers

- Defense/Aerospace

Contact Factory for Full Drawing

Contact Factory for Full Drawing

For Attenuator Block interfacing, the TR Multicoax connector must include shorter dowels and mounting screws.

Please be sure to note the requirement to mate with an Attenuator in your quote requests

Description

Description

Ardent’s high-density, solderless TR Multicoax and interposer technology, allows engineers launch a large amount of RF or digital signals in a small area, while being able to place connectors in unparalleled proximity to the device under test.

Light-tight form factors (with provisions to panel mount into a thermally conductive flange, disk, or other mounting plate) and all metal sockets and interposers available for chip-to-board and board-to-board connections are available.

Applications

- Dilution Refrigerators/Cryogenic Devices

- Quanum Computing

- Vacuum Chambers

- Defense/Aerospace

- Panel mount TR = feedthrough to light-tight enclosure

- Blind-Mate another TR to reach samples within enclosure

- Heat dissipation from the thermal anchor to the coax center conductor

- TR density allows higher # of coax lines

- 160 lines – 55mm x 85mm

- Fewer screws than SMA/SMP = faster install and reconfiguration

- High-density connectors bring coax lines closer to sample

- More signals + shorter trace

- Right angle FF for low clearance areas

- Light-tight enclosure

- Shielding cans

- Solderless connection

- Stable

- Reliable

- Reconfigurable

Contact Factory

"*" indicates required fields

-10 dB Crystalline Quartz Substrate SN 1087

-10 dB Crystalline Quartz Substrate SN 1087